Screen printing is the gold standard for bold color, durability, and cost‑efficiency on custom apparel. Here’s a quick look at how your idea becomes a crisp, long‑lasting print.

1) Artwork Preparation

We refine your design for clean printing—vectorizing where possible, separating each color into its own layer, and dialing in line weights and trap/knockout settings for perfect registration.

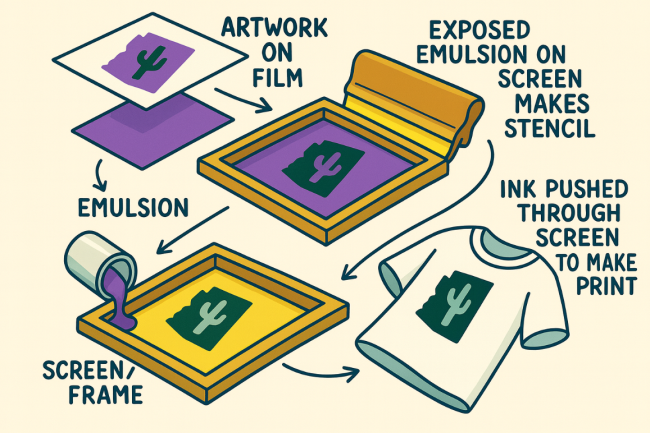

2) Film Positives

Each color gets a dense black film positive. These films will block UV light during exposure, creating the stencil that ink passes through. Multi‑color jobs = multiple films.

3) Coat the Screen with Emulsion

A photo‑sensitive emulsion is evenly coated onto a tensioned mesh screen and allowed to dry in a dark room. Smooth, even coats are key to sharp edges and strong stencils.

4) Exposure: Emulsion → Stencil

The film is placed on the coated screen and exposed to UV light. The emulsion hardens where light hits; the area blocked by the film stays soft. After a gentle washout, those soft areas rinse away—leaving open mesh that becomes your printable image.

5) Press Setup & Registration

We align (register) each screen on press so colors land exactly where they should. Off‑contact, squeegee durometer, angle, and pressure are dialed in for smooth ink deposit.

6) Printing

Ink is loaded and pulled across the screen with a squeegee, pushing ink through the open mesh and onto the garment. For dark shirts, we print a white underbase first, then flash cure, then lay down the colors for maximum pop.

7) Curing

Printed garments pass through a conveyor dryer to cure ink at manufacturer‑specified temperatures. Proper cure = wash durability and soft hand feel.

Why This Process Matters

- Durability: Correct mesh, exposure, and cure produce prints that last wash after wash.

- Color Accuracy: Proper separations and registration keep details sharp and colors aligned.

- Value at Scale: Once screens are set, larger runs are fast and cost‑effective.

Best Results: Our Pro Tips

- Provide vector artwork (AI, EPS, PDF) or high‑res (300 DPI) files at print size.

- Limit tiny text/halftones for small prints—keep details bold for best readability.

- Choose the right garment: ring‑spun cotton and quality blends print cleaner.

Share:

Start a Screen Printing Order See Our Screen Printing

Quick FAQs

Is screen printing better than DTG? For spot colors, durability, and medium/large runs—yes. We’ll recommend the best method based on your design and quantity.

Can you match brand colors? Absolutely. We can mix Pantone‑matched inks on request.

What’s the typical turnaround? Depends on complexity and quantity—reach out and we’ll get you a fast quote.